SUMPOT retort company was established in 1996s, with over 28 years of manufacturing experience in the food industry, SUMPOT offers a wide range of food sterilization equipment for various packaging formats. Today we will briefly introduce three main retorts that SUMPOT offers.

Classification by the state of the sterilization product during sterilization:

1. Static sterilization: There is no relative displacement of the sterilization product during sterilization, static.

2. Dynamic sterilization: The sterilization product has a relative position with the cylinder during sterilization, such as rotation, swinging, shaking back and forth, etc.

Heat transfer medium classification

1. Water Heat Transfer: Heat is transferred through superheated water. The circulating water is first heated by steam, and then the heat is transferred to the product through water, such as water spray sterilizer retort and water immersion sterilizer retort

2. Steam Heat Transfer: Direct heating through steam, such as steam sterilizer retort and steam air sterilizer retort

Introduction to Water Spray Retort

1. Three Types of Spraying: Top spraying, side spraying, top spraying + side spraying

2. Working Principle

1. Water Injection: Inject a proper amount of sterilization water into the bottom of the sterilization retort sterilizer.

2. Sterilization: The circulating pump circulates the sterilization water in a closed-circuit system, forming a mist that sprays onto the surface of the sterilized object.The temperature of the circulating water controlled within the required range. The pressure in the retort is adjusted through valves.

3. Cooling: The heat exchanger stops entering steam and starts to enter cooling water. The temperature of the circulating water is continuously reduced to the set temperature.

4. Drainage: Remaining sterilization water is discharged through the drain valve, and pressure is released through the exhaust valve.

Application Scope:

Glass jars,cans;PP bottles, HDPE bottles;aluminum foil bags, aluminum foil boxes, transparent bags, vacuum bags, high-temperature cooking bags, etc.

Equipment Features

Plate and shell heat exchanger with a long life and maintenance-free

1. Compact structure;

2. With hgh heat exchange efficiency;

3. Fully welded structure, for high pressure resistance;

4. No rubber pad, more heat-resistant and durable.

Integrated installation of heat exchanger and retort chamber

1. The design and installation structure of the heat exchanger is integrated with the retort body, and the structure is more compact;

2. Through integrated design, the number of connecting pipes is reduced;

3. The amount of sterilizing water used in the circulation process is reduced;

4. The heat dissipation of the pipe is reduced.

Introduction to Water Immersion Retort

Working Principle

1. Preheating: Fill the upper tank with water and let steam rise to the required temperature.

2. Drainage: Introduce the water from the upper tank into the retort chamber.

3. Sterilization: The circulation pump circulates the sterilization water in the closed-loop system, and the water overflows the sterilized object. As the steam enters the circulation pipeline, the temperature of the circulating water continues to rise and is finally controlled at the required temperature. The pressure in the tank is adjusted within the required ideal range through the pressure valve and the exhaust valve.

4. Recovery: Pump the sterilization water back to the upper tank.

5. Cooling: Cold water enters the retort chamber from the top, and the temperature of the sterilized object is continuously reduced. After entering the upper water level, turn on the circulation pump to fully contact the cold water with the product to achieve a cooling effect.

6. Drainage: The cooling water is pumped out through the circulating water pump, and the pressure in the retort is released through the exhaust valve.

Application Scope:

glass jars,cans;PP bottles, HDPE bottles;aluminum foil bags, aluminum foil boxes, transparent bags, vacuum bags, high-temperature cooking bags, etc.

Equipment Features

Better heat distribution, temperature deviation ≤+0.5℃℃

In order to improve the heat distribution effect, we modified the top water inlet to a branch form.

Unique support form, the gravity of the hot water tank acts on the ground to prevent flange deformation

A water spray box is added on the top to ensure the uniformity of the front and rear water flow and improve the heat distribution effect.

Use professional flow analysis software to calculate the actual flow difference to achieve the final required effect

The newly designed water vapor mixer has better heating effect and less noise

With a filter imported from Japan to prevent impurities from entering the valve and causing valve damage

Small pressure fluctuations, pressure control accuracy ≤0.1bar

With a gradual cooling function, it can ensure that the product is directly immersed in water

Introduction to Steam Air Retort

Working Principle

Heating: First turn on the steam and fan. Under the action of the fan, the steam and air in the retort chamber flow through the air duct in a front-to-back direction.

Sterilization: When the temperature reaches the set temperature, the steam valve is closed, and the fan continues to circulate. After the insulation time is reached, the fan is turned off; the pressure in the tank is adjusted to the desired ideal range through the pressure valve and the exhaust valve.

Cooling: If the amount of condensed water is insufficient, softened water can be added, and the circulating pump is turned on to circulate the condensed water through the heat exchanger for spraying. When the temperature reaches the set temperature, the cooling ends.

Drainage: The remaining sterilization water is discharged through the drain valve, and the pressure in the pot is released through the exhaust valve.

Application Scope:

Glass bottles, soft pouches, cans

Equipment Features

Reasonable steam expansion injection holes: To ensure steam circulation and prevent unfavorable steam circulation at the bottom of the product, our company

SUMPOT Advanced Water Spray Retorts

SUMPOT Advanced Water Spray Retorts

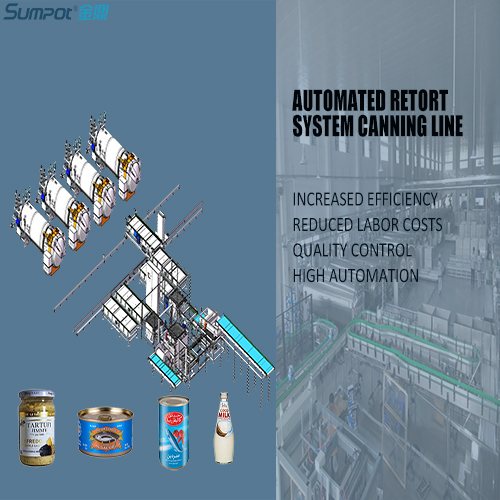

Automated Retort System Canning Line

Automated Retort System Canning Line