Description

Sumpot brand Retort machines, praised by domestic and foreign peers and customers for its excellent thermal sterilization performance and nanny-level after-sales service. As an industry leader and industry standard setter, SUMPOT has been focusing on and committed to food sterilization equipment to ensure food safety and longevity of packaged food products. Before you choose a retort equipment, how much do you understand it’s working principle, applications, and benefits on their indispensable role in your food or beverage production industry. Today you will have a comprehensive understanding on SUMPOT retort machines.

What is A Retort Machine?

The sterilization retort machine, also known as the food autoclave or food sterilizer, plays a vital role in the food industry. Retort equipment is mainly used to sterilize food or beverage that requires high temperature sterilization, such as meat,fish,dairy products, vegetables, pet food, babay food etc., to extend the shelf life and improve natural quality of packaged food.

Working Principle of SUMPOT Retort Machines

The working principle of Sumpot retort machines depends on the different sterilization forms of the product. Different retort autoclave has different working principles, generally speaking,they are an effective method of thermal processing sterilization utilizing high-pressure steam to eliminate harmful microorganisms from sealed containers of food. No matter which retort sterilizer you choose, the packaged food will be subjected to high temperatures and pressures in the retort chamber, effectively destroying pathogens, ensuring food safety and quality.

Applications of Sumpot Retort Equipment

Sumpot retort machines can handle different sizes and types of packaged food containers, allow for a wide range of versatility across the food packaging industry, including soft pouches, cans, glass jars, bottles, plastic trays and any other food packaging containers that are heat-resistance.

In addition, the applications of Sumpot retort machines are diverse and widespread across the food industry:

Canning: Sumpot retort machines are commonly used in canning industry, many of our customers request to sterilize their canned foods ranging from vegetables, beverages to meats and seafood, ensuring that all microorganisms, including bacteria, yeasts, molds, and spores are destroyed. Ensuring a long shelf life without refrigeration and preserving their natural quality.

Ready-to-Eat Meals: Ready-to-eat meals, also known as pre-packaged or convenience meals, as people's demand for fast food rises, retort equipment play a crucial role in sterilizing ready-to-eat meals, it can ensure food safety while retaining the good flavor and texture of the product as much as possible.

Beverages: Sumpot retort machines are also commonly used in the sterilization of beverage industry, such as juices and soups, maintaining their flavor and eliminating the risk of contamination, for example,coconut milk and chocolate milk, which people like to drink, can be sterilized by sterilizing in a sterilizer.

Why more and more companies pay more attention to choosing a better retort machine? Because the benefits of retort machines are extensive, making them an indispensable link in your food industry, as a leading manufacturer for food retort machines, SUMPOT retort machines show excellent sterilization performance in the industry as following:

Standardized Sterilization effect: During the sterilization process, the temperature and pressure are perfectly controlled according to different food processing techniques, the heat is evenly distributed, the pressure is smoothly controlled, the sterilization effect of each batch of products is consistent, the product packaging remains beautiful, and the deformation and breakage rates are reduced to a minimum.

High safety performance: Our retort machine is equipped with triple safety interlocks, the pot door flange is designed with a pressure relief structure to prevent the retort door from instantly popping open and causing safety accidents. The startup and operating condition detection can avoid safety problems caused by human errors. The full fault alarm function also allows users to grasp the status of the equipment during the sterilization process in real time to deal with faults at any time.

High degree of automation: All accessories are supplied by world-class component suppliers. The product quality is strictly monitored throughout the entire process. They have beautiful appearance, excellent workmanship and excellent stability.

Extended Shelf Life: The packaged food will extend their shelf life by sterilizing process with retort machines, meantime, retort thermal process can perfectly preserve the nutritional value, flavor, and texture of food, providing more confidence and convenience to consumers who enjoy fast food.

Versatility: Sumpot Retort machines can handle various packaging formats, such as cans, soft pouches, glass jars, bottles, plastic trays etc, and suitable for a wide range of food industry including meat, vegetable, dairy products,beans etc.

Energy Efficiency: Sumpot Retort sterilization shows excellent performance in energy saving, our original energy-saving designs minimize energy consumption during the heating and cooling cycles, reducing operational costs.

What services can you enjoy by purchasing our retort machines?

01. Pres-sales site survey and planning

02. Site planning, installation, commissioning, and user training before equipment use

03. Equipment on-site inspection

04. Scale cleaning and proportion formula provision

05. After-sales follow-up and sales door-to-door visits

06. Heat distribution or heat penetration test

07. Secondary equipment relocation and modification

08. Recall of defective equipment and parts

09. Lifelong maintenance of equipment

SUMPOT Advanced Water Spray Retorts

SUMPOT Advanced Water Spray Retorts

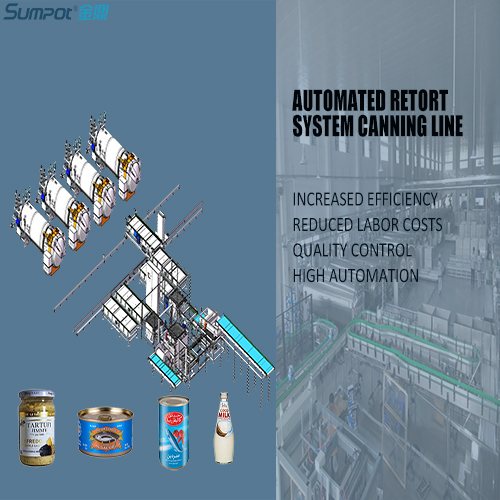

Automated Retort System Canning Line

Automated Retort System Canning Line

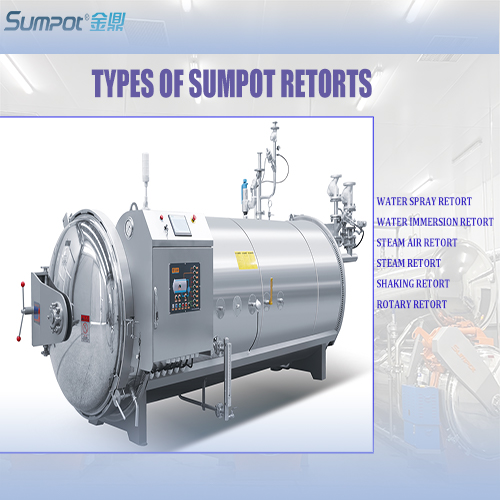

Types of Sterilization Retorts by SUMPOT

Types of Sterilization Retorts by SUMPOT