Canned fish is a ready-to-eat canned product made from fresh or frozen fish through processing, canning, adding seasonings, sealing, sterilization and other processes. The shelf life of canned fish can reach up to 24 months. People might think that is because it contains preservatives. In fact, this is not the case. Canning is an important food processing method, which is to put the raw materials in sealed containers and process them at high temperatures to kill various microorganisms and bacteria, destroy the activity of enzymes, prevent external pollution and oxygen from entering, so that the canned sardines can remain stable for a long time. Therefore, most canned fish products do not contain preservatives, consumers can eat them with confidence. So ensuring the safety and quality of canned sardines is becoming the crucial key through the whole process. One of the most effective methods is to use a high temperature and high pressure retort machines(autoclaves) to effectively sterilize canned sardines,today we will learn how canned sardines are sterilized in a retort machine.

What is retort sterilization process?

Retort sterilization is an effective thermal processing method used in the food or beverage industry, designed to extend the shelf life and improve natural quality of packaged foods. Retort machines can handle different sizes and types of food containers, such as cans, pouches, trays, bottles,cans are loaded into specific retort machine,starting the sterilization process at a set temperature and a pressure for a predetermined period.This process effectively destroys harmful microorganisms and bacteria,ensuring the safety,quality and shelf life of the packaged foods.

Canned Sardines sterilization process

Canned Sardines sterilization process in retort machines abides by a systematic process to guarantee effective treatment. The process basically includes these steps as following:

Preparation: Before sterilization, the sardines are cleaned and packed into cans along with brine or oil and any desired flavorings. Then make sure the tunas can be sealed and packaged well in cans. Before putting the canned sardines into the retort machines, the operator needs to check whether there are other debris in the retort equipment. After confirming that there is nothing wrong, push the cans into the retort cooker.

Loading: The sealed cans filled with sardines are loaded into the retort machinery, after entering the retort sterilizer, you need to first check whether the sealing ring of the retort door is damaged or out of the groove. After confirming that it is normal, close and lock the door. Place the cans in an orderly manner to achieve uniform heat distribution and heat penetration during sterilization.

Sterilization: Close the retort door, start the program automatically set on the control panel and the sterilization program begins. Adjust the steam pressure in the retort equipment to the required pressure and maintain the pressure and temperature for a certain period of time to achieve the sterilization effect. Until The temperature is finally increased to around 121°C (250°F), to hold this high temperature for a period of time,ranging from 50 to 90 minutes, depending on different size of the cans and the type of fish food being processed.

Cooling: Turn off the heating system, add cooling water into the retort cooker, and gradually lower the high temperature. When the temperature in the retort machinery is decreased to a certain level, the cooling is completed and the waste water in the retort cooker is discharged. the steam is vented from the retort, and the cans are cooled rapidly to prevent overcooking, so the canned sardines can retain a good natural flavor.

Quality Control: Sumpot brand of sterilizer retort adopts a linear control system with high precision. It can accurately control the amount of steam entering during the insulation process. The temperature accuracy can reach about ±0.2℃ and the pressure is about ±0.01Mpa.When cooling, the amount of cold water entering can be adjusted, and rapid or slow cooling can be achieved according to process requirements. The cooling speed is proportional to the cooling time according to the process setting, so as to achieve the purpose of synchronizing the internal temperature with the external temperature and stabilize the sterilization effect of the product. The Sumpot pressure control system ensures precise pressure control and effectively prevents product deformation and can collapse.

Packaging and Distribution: After sterilization, the cans of sardines are ready for cooling completely before being packaged and labeled, then prepared for distribution.

Benefits of Retort Sterilization

Standard Sterilization effect: Retort sterilization effectively destroys harmful microorganisms, like bacteria, yeasts, and molds,extending shelf life and improving natural quality and safety of canned sardines.

Preservation of Nutritional Value: Retort sterilization preserves the nutritional value, taste and texture of canned sardines, providing consumers with a high-quality product. After high temperature and high pressure sterilization process, the microbial indicators of canned fish meet the commercial sterility requirements, and the shelf life can be up to 2 years or more.

Versatility: Sumpot retort sterilization equipment can process a wide range of food products, such as fruits, vegetables, meats, seafood, dairy products,and ready-to-eat meals, in various packaging formats such as cans, jars, pouches, glass jars,and trays.

Above all, the safety and quality of canned sardines benefit from effective sterilization effect in the whole production link. Their efficiency, Convenience and Versatility, and cost-effectiveness make them indispensable equipment for food manufacturers worldwide, providing consumers confidence and trust in the product purchasing.

SUMPOT Advanced Water Spray Retorts

SUMPOT Advanced Water Spray Retorts

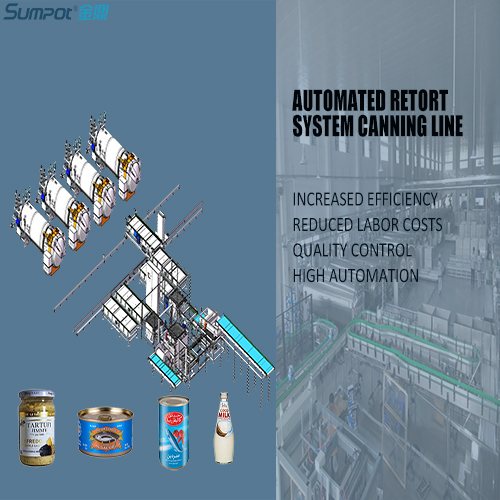

Automated Retort System Canning Line

Automated Retort System Canning Line

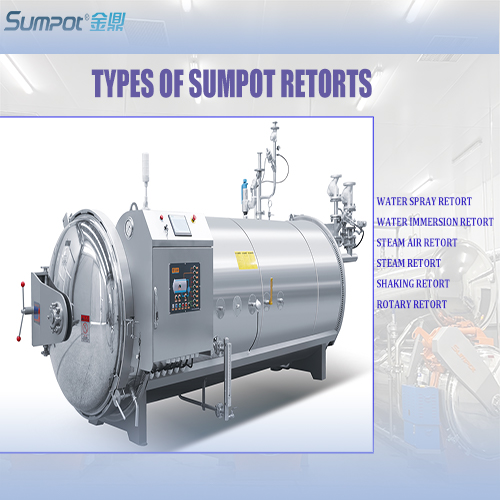

Types of Sterilization Retorts by SUMPOT

Types of Sterilization Retorts by SUMPOT