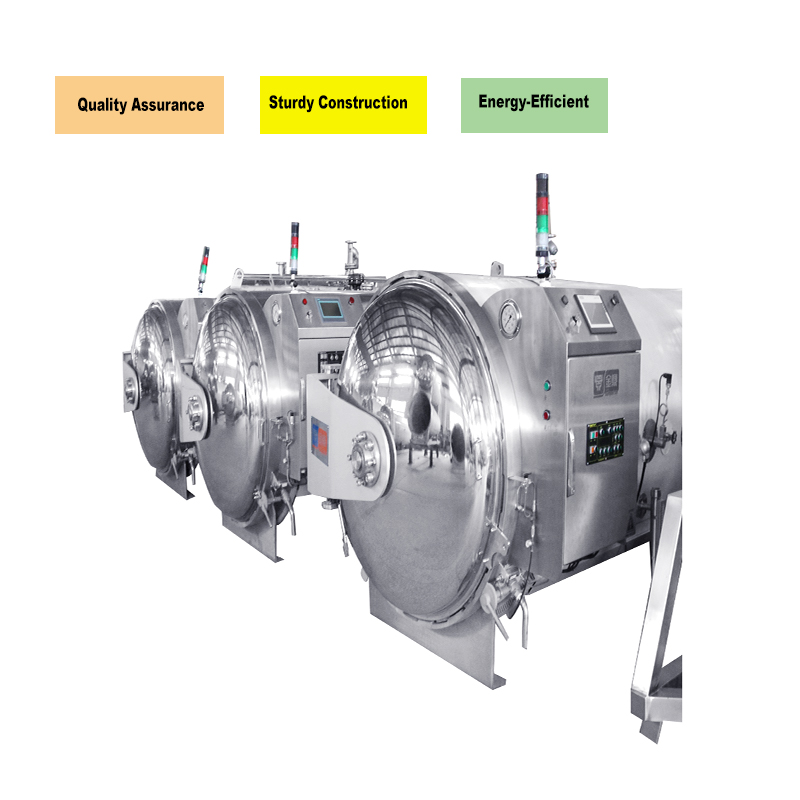

Product Details:

Water spray retort machine injects a small amount of process water to a predetermined position. The water is injected into the spray pipes through a high-efficiency circulation pump-filter-high-efficiency heat exchanger, and then the hot water is sprayed out through the spray nozzle to atomize it. shape to the surface of the food, the heat is evenly distributed in the retort, and there are no sterilization dead corners. The water is indirectly heated and cooled through the heat exchanger. The heating and cooling speeds are rapid, and the product can be sterilized efficiently, comprehensively and stably.

Working Principle:

1. Water injection: Inject an appropriate amount of sterilizing water into the bottom of the retort machine.

2. Sterilization: The circulation pump continuously circulates the sterilization water in the closed-circuit system. The water forms a mist and is sprayed onto the surface of the sterilization products. As the steam enters the heat exchanger, the temperature of the circulating water continues to increase, and is finally controlled at the required temperature. The pressure in the retort is adjusted within the required ideal range through the pressurization valve and exhaust valve.

3. Cooling: When the exchanger is changed, steam is stopped and cooling water is started to flow. The temperature of the circulating water is continuously lowered to the set temperature.

4. Drainage: The remaining sterilization water is discharged through the drain valve, and the pressure in the retort machine is released through the exhaust valve. Apllication Industry: Food & beverage products high temerpature high pressure sterilization

Apllication Industry: Food & beverage products high temerpature high pressure sterilization

Packaging Applications: All kinds of heat resistant packaging materials including pouches,tin cans, bottles, glass jars, trays.

Equipment Advantages:

1. Accurate temperature control system with uniform heat distribution

The temperature control system can be linear or non-linear according to different products. The temperature can be accurately controlled within ±0.5°C and the heat distribution and heat penetration is uniform.

2. Precise pressure control

The pressure control system continuously adjusts the pressure changes inside the packaging. The pressure can be controlled at ±0.05Bar, it is suitable for a variety of packaging forms.

3.Standardized sterilization effect During the sterilization process, the temperature and pressure are perfectly controlled according to different food processing techniques. The sterilization effect of each batch of products is consistent, the product packaging remains beautiful, and the deformation rate and breakage rate are minimized.