Description:

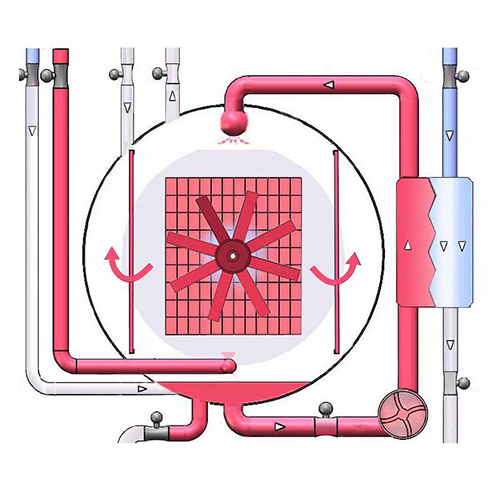

The steam air retort provides a heat source to the sterilization retort through two steam distribution pipes installed at the bottom. No exhaust process is required. The large-flow axial flow fan installed in the sterilization retort fully mixes the cold air and steam in the retort. It is then used as a heat transfer medium to evenly heat and sterilize the canned food in the sterilizing retort. Since the fan in the retort is carefully designed, the sterilization process does not require an exhaust process. The large-flow fan can remove the air in the pot. The air bags are fully dispersed and mixed with steam as a heat transfer medium for sterilization, with uniform temperature and no cold spots. The steam mixture is forced to circulate in the sterilizing retort through the air duct. The heat in the sterilizing retort is evenly distributed, which can meet the requirements of the thermal sterilization process of canned food in various packaging types.

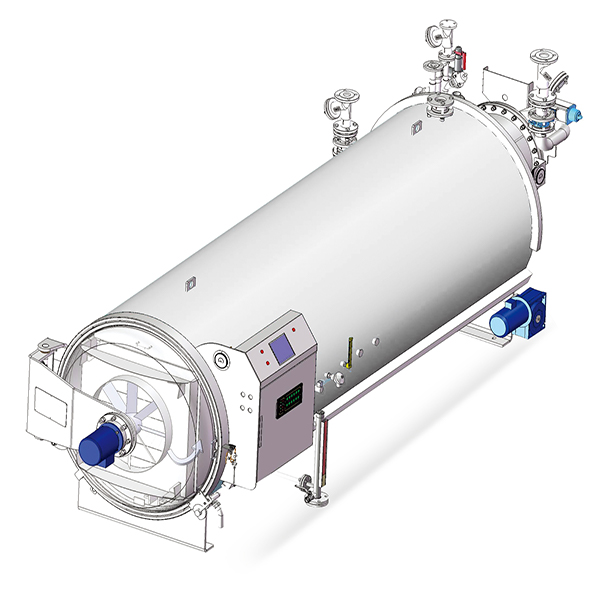

The sterilizing retort is mainly composed of a cylinder part, a pneumatic part, a transmission part, an electronic control part, etc. The cylinder is welded from acid-resistant and heat-resistant austenitic stainless steel, and the pot door adopts a quick-opening form, with reliable sealing and advanced structure; the pneumatic part includes pneumatic angle seat valves, pneumatic butterfly valves, cylinders, etc.; the transmission part includes reducers, tracks , water pumps, etc.; the electronic control part includes display screen, control box, control panel, temperature sensor, pressure sensor and other components.

Application:

Suitable for all heat resistant and waterproof package material except casing

1. Glass container: Glass bottle, glass jar

2. Metal can : Tin canned, aluminum can

3. Plastic container serial: PP bottles, HDPE bottles

4. Flexible pouch serial: flexible retort pouch, laminated film bag, high temperature cooking bag, vacuum bag

Steam air working principle

Step 1: heating process

Start the steam and fan first. Under the action of the fan, the steam and air in the kettle flow forward and backward through the air duct.

Step 2: Sterilization Process

When the temperature reaches the set temperature, the steam valve is closed and the fan continues to run in the cycle. After the holding time is reached, the fan is turned off; the pressure in the tank is adjusted within the required ideal range through the pressure valve and exhaust valve.

Step 3: Cool down

If the amount of condensed water is insufficient, softened water can be added, and the circulation pump is turned on to circulate the condensed water through the heat exchanger for spraying. When the temperature reaches the set temperature, the cooling is completed.

Step 4: Drainage

The remaining sterilizing water is discharged through the drain valve, and the pressure in the pot is released through the exhaust valve.

Steam air retort features:

1. There is no need for steam cooling. Compressed air can be injected into the kettle. The turbine fan rotates to break up the air cooling mass, forcing the steam and air mixture to circulate in the kettle without cold spots. The heat distribution during the sterilization stage is controlled at ±0.5°C;

2. The ventilation turbine blower forces the steam-air mixture from one end of the kettle to the other, adsorbing it to all products, avoiding the problem of turbulence in the ventilation system and saving more than 15% of steam;

3. The driving backlight plate is designed according to the principle of aerodynamics. The steam sucked in from its starting point can control the flow direction and accelerate the heat transfer to the center of the product for heating and cooling;

4. The pressure and temperature can be controlled more freely, and counter-pressure cooling can be carried out;

5. It can be applied to all high-temperature sterilization products such as snack foods, meat products, beverages, etc. in various packages;

6. Equipped with a negative pressure safety device to avoid manual misoperation and the formation of negative pressure to ensure the safety of the equipment;

7. After the equipment is restored after a power outage, the program can automatically restore to the state before the power outage to reduce losses;

8. Equipped with triple safety interlocks to prevent workers from misoperation and avoid accidents;

9. Use dual safety valves and dual pressure sensor controls to eliminate potential safety hazards.

Other advantages:

1. The steam air retort allows pressurization during the heating and heat preservation stages, so it can be used in flexible packaging;

2. The fan motor is controlled by a frequency converter, which can slowly start and stop, effectively protecting the motor, bearings and other components;

3. A proportional regulating valve can be used to control steam, which can design multi-stage temperature rises, achieve linear control, and ensure the standardization of sterilization products.

4.Save energy: Compared with traditional steam sterilization, no exhaust is required, saving about a quarter of steam. Compared with water immersion and spray sterilization, water is not used as the intermediate heat transfer medium, which saves the steam consumption of heating water.

keywords: retort machine,autoclave machine,food retort, food sterilization, retort system, retort processing, industrial autoclave,canning retort machine, autoclave for canned food