Nowadays, food packaged in soft bags can partially replace food packaged in metal and glass jars. The materials used in soft bag packaging are small in thickness, have fast heat transfer, and short sterilization time, and can better maintain the original color, aroma, and taste of food; Packaging materials are light in density and small in size, saving space and easy to transport; they have a long shelf life and are easy to eat, and can use sterilization technology and equipment for canned food in metal cans and glass bottles. However, the packaging material strength of soft bag packaging is low. Although many companies have strictly controlled the people, materials, materials and other aspects of the secondary sterilization of high-temperature retort bag food, the products produced are still unsatisfactory, and the soft bag damage rate High, "overburning" and "cold spot" phenomena are frequent, resulting in low output rate and serious waste of materials.

Nowadays, the sterilization equipment used for secondary sterilization of soft bag food is mainly intermittent static sterilization equipment, including "steam sterilization retort", "water immersion type" and "water spray type sterilization retort". "Steam sterilizing retort" is a traditional sterilizing equipment. Due to the presence of air in the retort during the sterilization process, cold spots will appear, causing uneven temperature distribution and inconsistent sterilization quality. Exhaust measures need to be adopted to discharge part of the steam into the atmosphere ( Accounting for about 25% of heating sources), it causes a large waste of energy, causes noise and pollution to the workshop, and is not conducive to the development of the company and society. "Water-immersed" equipment is large in size and complex in operation. It is mainly used for sterilizing iron cans of meat products.

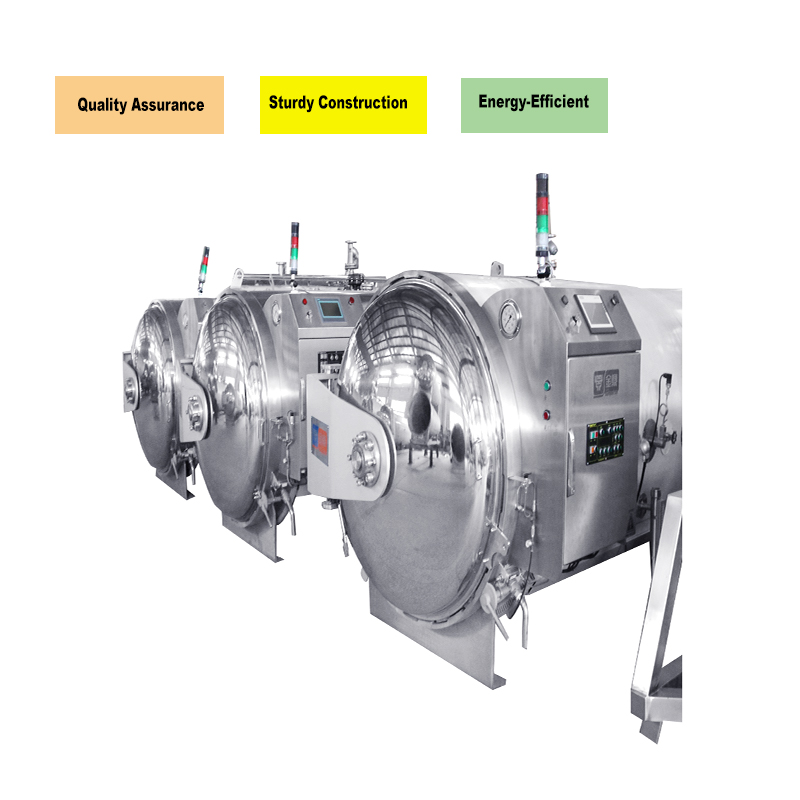

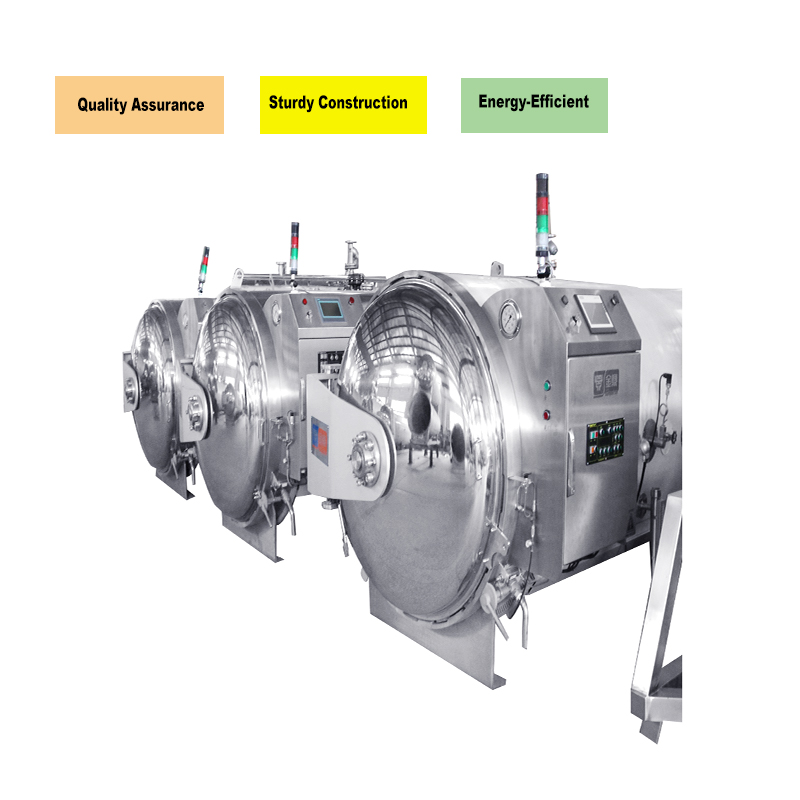

"Water spray sterilization pot" is divided into two types: "side spray" and "top spray". It is a new generation of sterilization equipment that entered my country in the 1990s. Ningbo Ruituo Sterilization Equipment Co., Ltd. was the first to produce " Fully automatic water spray sterilizing retort" enterprise. The sterilization process is through numerous nozzles located on both sides or at the top of the retort, spraying mist-like wavy hot water onto the surface of the food. It also heats up and cools quickly, and can sterilize the products in the retort comprehensively, quickly and stably. , especially suitable for sterilizing food in high-temperature cooking bags.

The difference between the water spray sterilization method and the traditional high temperature and high pressure sterilization method is:

Adopting "precise back pressure control in the pot" technology and "wavy hot water injection" method. Since the materials used in soft bag packaging are generally sensitive to cold and heat and are easily damaged, the new water-sprinkling sterilizingretort adopts unique technology and water-spraying methods, which can achieve a pressure error of less than 0.01mpa and a temperature error of less than 0.3°C in the retort, making the retort The inner product can be completely and evenly pressed and heated;

Adopt "real-time flow accurate measurement" device. Control the spray status in the pot at any time to ensure that the soft bag products in the pot are heated evenly and avoid "cold spots";

The entire process of heating, heat preservation and cooling of the new water-sprinkling sterilizing retort is controlled intelligently by PLC and the "fully automatic touch screen" is the human-machine interface. The multi-stage heating and cooling process can reduce the temperature difference between the surface and center of soft bag food. The rising and falling temperature can reach 16 levels, which is more than twice that of ordinary domestic sterilizing retorts. All parameters can be input easily through the PLC touch screen, and 30 sets of sterilizing parameters can be stored in advance. When changing material types, you only need to call up the relevant sterilizing parameters. ;

Heat distribution measurement. Each sterilizing retort needs to undergo strict heat distribution measurement before leaving the factory, and the temperature error is strictly controlled within 0.5°C to ensure the safety and reliability of each bag of product in the pot during the sterilization process;

Cooling water and sterilization water are separated. What comes into contact with the flexible packaging bag during cooling is high-temperature sterilized circulating water, which will not cause secondary pollution to the flexible packaging bag. The cooling water will not be contaminated by the material grease adhering to the surface of the flexible packaging bag. At the same time, it can be recycled and save water. , greatly reducing production costs;

high degree of automation. When the sterilization basket containing the product is pushed into the sterilization

retort, just press the start button, and the entire sterilization process of heating, constant temperature sterilization, pressurization, pressure reduction, and cooling is automatically completed.

SUMPOT retort company develops various types of water spray sterilization retort machines in the past 28 years, we have rich experience of manufacturing retort machines per different packaging containers, our retort macines have exported to more than100 countries, for water spray type of sterilization retorts, we have 3 different spray modes, top spraying, side spraying , top and side spraying method, for each type, the retort can achieve different effects for packaged food sterilization.