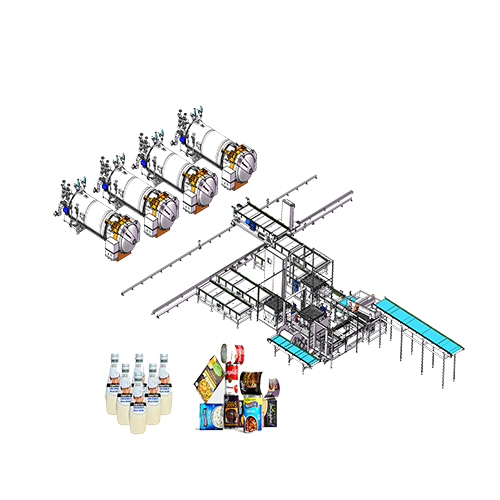

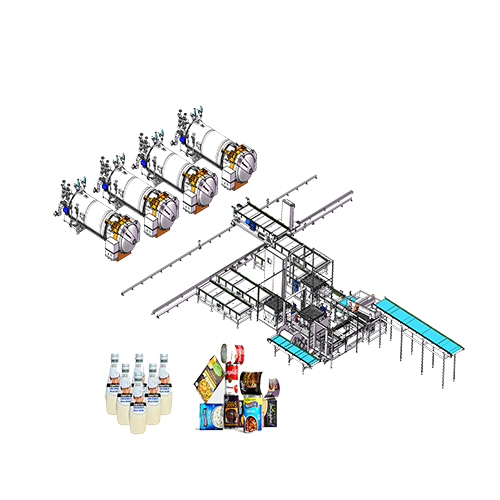

The canning processing production line refers to a production line that integrates food processing, cooking, filling, sealing, sterilization and other processes. Mainly used to produce canned food, such as canned vegetables, fruits, meat, seafood and other food cans. The purpose of the canning processing production line is to improve production efficiency, reduce production costs, and ensure product quality and health safety. Canning processing lines usually include the following processes:

Food cleaning: preprocessing raw materials such as cleaning, peeling, and seed removal;

Food cutting: cutting, slicing, shredding, etc. the washed food;

Food cooking: cooking cut food, such as boiling, stewing, roasting, etc.;

Filling and sealing: filling cooked food into cans and sealing;

Sterilization and cooling: Sterilize the cans to kill bacteria to ensure product quality and safety, and then cool them; SUMPOT retort company has developed advanced retort system canning processing lines, which is used for canning food sterilization process. It is mainly used for automatic cage loading, automatic entry and exit of canned products before sterilization, automatic cage unloading after sterilization, etc. The front end can be connected to the canning sealing machine through a conveyor belt, and the back end can be connected to the cleaning and packaging line through a conveyor belt to achieve unmanned production in the sterilization workshop. The loading and unloading equipment can realize automatic caching, automatic turnover of empty cages, automatic entry and exit of the retort machines(autoclaves), etc. The entire loading and unloading line is controlled by an intelligent system to achieve unmanned production.

Packaging and labeling: Pack and label the sterilized and cooled cans;

Finished product inspection and storage: Conduct finished product inspection on the packaged cans to determine whether the product quality meets the standards, and perform storage and processing.

The advantages of canning processing lines are as follows:

High production efficiency: The canning processing production line adopts automated equipment and has high production efficiency, which can greatly improve production efficiency;

Low production cost: The canning processing production line has a high degree of automation, low labor costs, and low production costs;

Produce high-quality products: The canning processing production line uses professional equipment and strictly controls product quality during the production process to ensure high-quality products;

Hygienic and safe production process: The canning processing production line uses automated equipment, which reduces manual operations during the production process and is highly hygienic and safe;

Stable production process: The canning processing production line adopts automated equipment and the production process is stable, which can ensure stable quality of the production process.

To sum up, the canning processing production line is a production line that integrates food processing, cooking, filling, sealing, sterilization and other processes. It has high production efficiency, low production cost, high product quality, hygienic and safe production process, and stable production process. and other advantages, it is widely used in the field of canned food production.