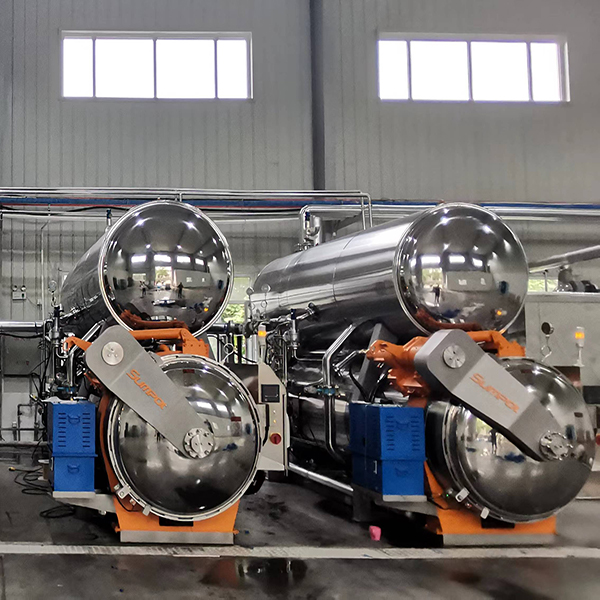

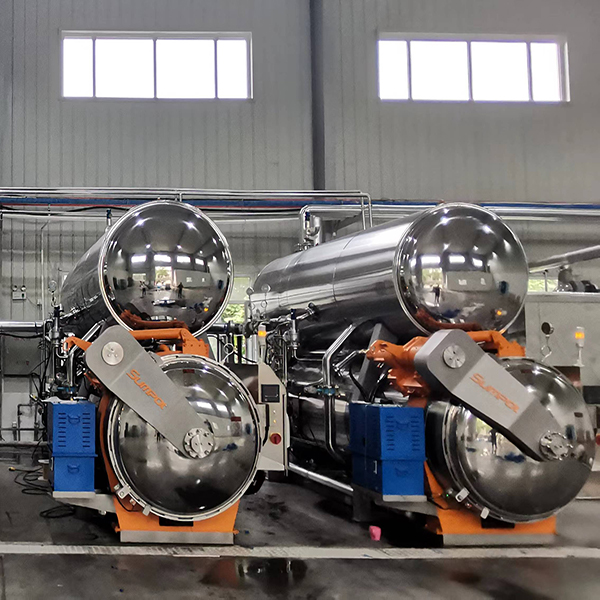

The entire sterilization process of the sterilizing retort adopts PLC fully automatic linear control. The temperature inside the tank is controlled at ±0.2°C. The multi-stage temperature control can ensure heating, constant temperature and cooling segmented control and powerful delay function. High-fidelity pressure simulation curve control ensures The sterilizing

retort adopts our mature sterilizing temperature recording system technology for the pressure compensation, back pressure and sterilization of special products during the canned sterilization process. The control system is connected to the computer through RS485 communication. The system can The entire sterilization control process can be displayed in real time, and the temperature and pressure curve of the sterilization process can also be automatically stored in the computer, and the user can check it at any time. It can also be printed at any time through a printer, which can realize remote control of the factory and remote data management. The purpose of the sterilizing

retort is Sterilize various products suitable for high-temperature sterilization so that the products can be stored at normal temperatures for a longer period of time.

Users can choose water spray sterilization retorts or water immersion sterilization retorts, which are suitable for soft packaging of canned food, meat, fish, corn, vegetables, dairy products, etc., as well as tinplate cans and glass bottled products. The rotary type main steam sterilization retort stainless steel is used for eight-treasure porridge. In the production of other products, the product is rotated in the pot during the high-temperature sterilization process to solve the problem of various viscous canned foods with different concentrations. The canned food will not stratify or precipitate during the shelf life. By calculating the required amount of food in the retort at this temperature Pressure, automatically control the opening and closing of the inlet and exhaust valves, so that the pressure in the high-temperature sterilizing

retort has a certain relationship with the temperature during the entire sterilization process.

The working principles of water immersion retorts and steam retorts are different:

1. The water immersion retorts directly inject steam to heat the water in the hot water tank to a predetermined temperature, and then injects it into the process tank. At the same time, the process water in the pot is continuously circulated and heated and sterilized through the water-vapor mixer. This shortens the sterilization time and improves work efficiency. The sterilized process water can be recycled, saving energy, time and consumption of manpower and material resources, and reducing production costs.

2. The steam-type sterilizing retort uses steam generated by the boiler at a certain pressure as the heat source, and uses high-temperature saturated steam to sterilize the product. It has the characteristics of fast heating speed, high thermal efficiency, uniform heating, and easy control of the heating temperature. The inner layer of the sterilizing retorts, the pot body is made of acid-resistant and heat-resistant stainless steel, equipped with a pressure gauge and a safety valve. It has beautiful appearance, easy installation, convenient operation, safety and reliability.

Water immersion retorts and steam retorts have different application ranges:

Water immersion retorts are suitable for all types of high temperature resistant packaging materials:

1. Plastic containers: PP bottles, HDPE bottles

2. Soft bag packaging: aluminum foil bags, transparent bags, vacuum bags, high temperature cooking bags, etc.

3. Tinplate cans, aluminum cans and glass bottle products

Scope of application of steam sterilization retort: canned meat products, canned drinks, canned fruit and vegetable products, glass bottled fruit and vegetable products and other products, such as lunch meat, black bean fish, sardines, canned beef, coconut juice, walnut juice, winter melon tea, Sea buckthorn drink, canned asparagus, sweet noodle sauce, etc.

sumpot retort company has a 28-year of manufacturing various types of sterilization retort machines in China, we have professional team to give professional solutions based on customers' food beverage sterilization request, if you are looking for this type of sterilization retorts, please feel free to fill out our inquiry form, we will contact you soon.