SUMPOT is the leading manufacturer in China for retort sterilization equipment, one of our advanced retort machines is steam air retort, which is a high temperature high pressure vessel mixing steam and air as the heating medium to sterilize different types of packaged food,including glass bottles, tin cans, plastic cups/trays,soft pouch, jars etc. We have more than 28 years of experience in manufacturing steam air retorts. Here are some features of steam and air retort machines.

A steam air retort is a type of equipment used in the food industry to sterilize food products, especially for canned packaged foods. The process using heat and pressure mixing steam and air to kill microorganisms, enzymes, and other pathogens that could cause health problems, ensuring the long-term shelf stability of the food product.

Sterilization: It combines saturated steam and hot air to heat the contents of food. This brings effective penetration of heat into the food,sumpot adopts the high power fan to mix the hot air and steam, Reasonable steam expansion injection holes: In order to ensure steam circulation and prevent unfavorable steam circulation at the bottom of the product, our company adopts the design concept of steam segmented injection. All injection holes are located in the middle gap between baskets.

Temperature and Pressure Control: For example, the heat distribution of397g luncheon meat: during the entireheat preservation process, the maximumdifference between the temperature ateach point and the control temperatureis 0.45 degreesInsulation stage: When entering the heatpreservation stage, the temperature ofeach point remains in a polymerizedstate without discreteness。

Energy Efficiency: The steam air retort does not require exhaust and doesnot use sterilizing water as a heat transfer medium, socompared with other forms of retort, the energy savingeffect is very obvious. Actual measurement data using flow meters previouslyshowed that the steam savings could reach 51%

Versatility: Choice of cooling form: Different cooling forms can be selected according to different product packaging forms, suitable for flexible packaging and tinplatecans.

Other advantages:

5. The steam air retort allows pressurization during the heating and heat preservation stages, so it can be

used in flexible packaging;

6. The fan motor is controlled by a frequency converter, which can slowly start and stop, effectively

protecting the motor, bearings and other components;

7. A proportional regulating valve can be used to control steam, which can design multi-stage temperature

rises, achieve linear control, and ensure the standardization of sterilization products.

keywords: retort machine,industrial autoclave,food retort, retort processing,food sterilization,steam retort,retorting technology

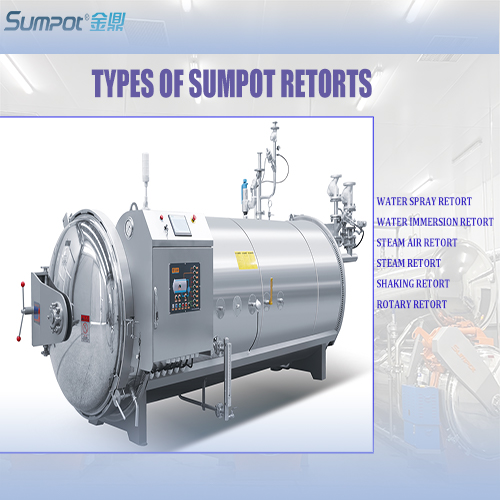

Types of Sterilization Retorts by SUMPOT

Types of Sterilization Retorts by SUMPOT

SUMPOT Water Immersion Retort Machine

SUMPOT Water Immersion Retort Machine

Introduction To SUMPOT Retort Machines

Introduction To SUMPOT Retort Machines