Introduction

Water immersion retort is one type of sumpot sterilization equipment, it is known as excellent heating penetration and energy-efficient in food industry.It consists of an upper hot water storage tank and a lower sterilizing retort. The hot water storage tank is the same size as the retort equipment. The water in the upper tank is heated to a preset temperature, and then the hot water is injected into the retort machine. The sterilizing water is circulated and heated through a water vapor mixer. During sterilization, all the food within retort machine is soaked completely in hot water, which can achieve 360 degree no dead corner sterilization of the product. Water bath sterilization is particularly suitable for irregular large packaged products, because water heat transfer is relatively fast, and there will be no uneven heating and incomplete sterilization.

Application:

Sumpot water immersion retort is commonly used for Vacuum packaging bags/large packaged products, which are weight greater than 1KG/products with very viscous contents, products that are difficult to penetrate with heat, such as vacuum packaging bags of corn, large packages of chicken and beef, etc. Compared with other types of retort equipment, large packaged products can be completely immersed in water, so heat penetration is faster, products are more easily heated evenly, and better sterilization effects are achieved.

Working principle

1. Preheating: Fill the upper tank with water and introduce steam to raise the temperature to 121 degrees.

2. Drainage: Introduce the water from the upper tank into the sterilization retort.

3. Sterilization: The circulation pump circulates the sterilization water in the closed-loop system, and the water overflows the sterilized object. As the steam enters the circulation pipeline, the temperature of the circulating water continues to rise and is finally controlled at the required temperature. The pressure in the tank is adjusted within the required ideal range through the pressure valve and the exhaust valve.

4. Recovery: Pump the sterilization water back to the upper tank.

5. Cooling: Cold water enters the retort chamber from the top, and the temperature of the sterilized object is continuously reduced. After entering the upper water level, turn on the circulation pump to fully contact the cold water with the product to achieve a cooling effect. "

6. Drainage: The cooling water is pumped out through the circulating water pump, and the pressure in the retort chamber is released through the exhaust valve, the whole sterilization process is completed.

Advantages of Sumpot water immersion retorts

1. Reasonable pipeline layout: There are 3 ways to drain water from the upper and lower retort machine, 1 in the middle and 2 on the bevel, so the drain speed is fast; fast drain speed, the average drain time is only within 2.5 minutes.

2. Large water pump ratio: 3-5 cycles can be made in 1 minute. A large flow water pump is used. The larger the pipe diameter, the larger the valve, the faster the overall temperature rise of the product, the smaller the temperature difference inside the product, and the smaller the temperature difference between the upper and lower layers of the product.

3. A water spray box is added to the top to ensure the uniformity of the front and rear water flow and improve the heat distribution effect.

4. Uniform heat distribution: Through the water vapor mixer, water and steam are fully mixed instantly, reducing the internal heating time of the product and improving the heat distribution performance. The temperature difference between the lowest and highest points is 0.21℃, and the standard requirement of the US FDA is to reach 0.56℃.

5. In order to improve the heat distribution effect, we modified the top water inlet to a branch outlet.

6. Unique support form, the gravity of the hot water tank acts on the ground to prevent flange deformation.

7. The steam inlet and compressed air inlet are equipped with filters to prevent impurities from entering the valve and causing valve damage.

8. The cooling water inlet form has been modified:

The original bottom cooling water inlet has been changed to the top cooling water inlet. To ensure pressure stability, a small cooling water inlet valve has been added. Cool water is introduced from the top, and the cool water will flow through the product to the bottom, which can reduce the temperature difference between the upper and lower products. Reduce the difference in sterilization intensity.

9. Better heat distribution Temperature deviation ≤±0.5℃; small pressure fluctuation Pressure control accuracy ≤0.1bar (≤0.01Mpa)

10. The sterilization axe is equipped with low point (cold point) dual temperature detection + high point temperature detection to better control the temperature of the upper and lower parts of the axe

11. Water vapor mixer: uniform heating, reduced temperature difference, quiet operation, and no hammering.

For more information on our water immersion retort machines, please feel free to fill out inquiry form, we will contact you as soon as possible.

SUMPOT Advanced Water Spray Retorts

SUMPOT Advanced Water Spray Retorts

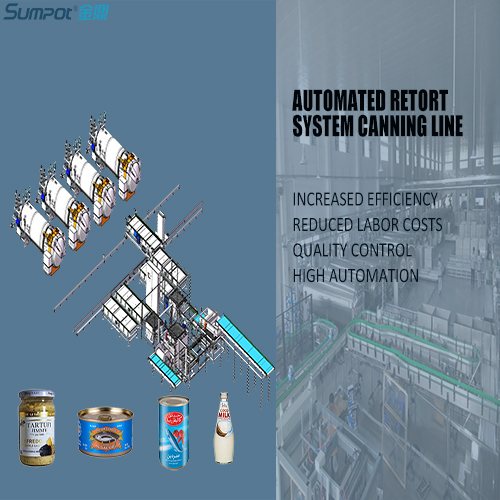

Automated Retort System Canning Line

Automated Retort System Canning Line

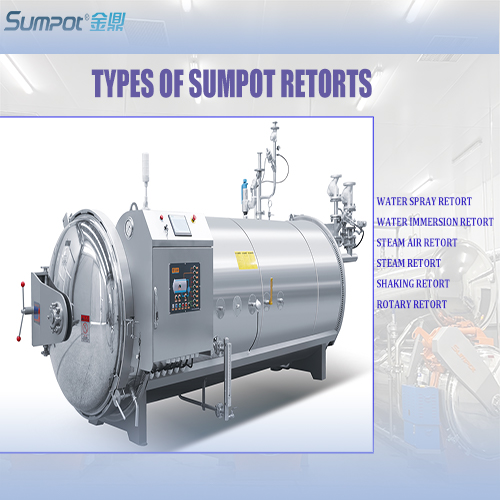

Types of Sterilization Retorts by SUMPOT

Types of Sterilization Retorts by SUMPOT