Currently, there are two main categories of common canned pet foods on the market based on nutritional types: full-price and balanced canned products and snack canned products.

Most canned foods have a water content of about 70%, and some are even as high as 84%. The high water content makes the product very palatable and very attractive to picky pets.

Canned pet foods often contain higher levels of fresh or frozen meat, poultry, or fish or animal by-products. Meat-based canned foods may contain 25% to 75% meat or meat by-products. Full-price canned food also adds grains, plant proteins, vitamins, minerals, etc. to ensure comprehensive and balanced nutrition. However, the complexity of the processing process makes the processing cost higher, so the price is more expensive.

The processing process of canned pet food is much more complicated than that of dry food. Usually, the meat and fat ingredients are first mixed with a certain amount of water, and then an appropriate amount of dry ingredients are added, such as vitamins, minerals, amino acids and other similar substances. These ingredients are then mixed, and if you want the food to have a good texture, the mixture needs to be ground into a very thick slurry.

The mixture can be heated (or steamed) to begin the subsequent cooking process, or it can be filled directly into the can via a filling can. After filling, the jars are sealed with double-slit lids and retorted. The retorting process is actually a heating and pressurizing cooking process, and it is also a sterilization process that can inactivate pathogenic bacteria in food.

After retorting, the canned pet food must be cooled and dried before being labeled with a product code. These processing techniques enable the product to maintain a long shelf life.

The commercial pet food industry has produced a wide variety of canned pet foods, with choices in varieties and textures including foods containing large pieces of meat or small amounts of meat-like foods, ground meats, large roasted foods, and foods with Juicy chunks, as well as traditional foods that have been crushed and have a texture. At the same time, not all canned food is packed in cans. Current technology can use soft bags or other new containers for retort. This type of food is also called "wet" pet food.

Because the manufacturing process of canned food includes heating and pressurizing processes, it is likely that some important nutrients are destroyed. For example, thiamine (vitamin B1) is easily destroyed by heat, especially under neutral or alkaline conditions, so it is lost in large quantities during the manufacturing and storage of canned pet food. One study showed that the amount of thiamine in canned dog food was reduced by 74% after retort and storage for 14 days. Various well-known pet food manufacturers have conducted extensive research to determine the extent of these nutrients being lost during processing and overdosing in formulas to compensate for this loss.

The main purpose of sterilizing canned pet food is to prevent the contents of the can from being damaged by microorganisms, etc., so as to meet the requirements of commercial sterility.

The heat transfer media for sterilization are generally hot water and steam, with steam being the most widely used. The heat transfer from the sterilizing heating medium to the outer wall of the tank is mainly carried out by convection and conduction. The heat transfer from the outer wall of the tank to the inner wall of the tank is by conduction, while the heat transfer method from the inner wall of the tank to the coldest point in the center of the content depends on the nature of the content. and canning conditions. Depending on the nature of the raw materials, sterilization methods usually include atmospheric pressure sterilization and pressure sterilization.

The process conditions for heat sterilization of canned pet food are mainly composed of three factors: temperature, time and pressure, and are commonly expressed as sterilization formulas. The process includes three stages: heating, preservation and cooling. Sterilization formula = (t1-t2-t3)/T.

In the formula: t1 - the time required to heat up to the sterilization temperature, min; t2 - the time required to maintain a constant sterilization temperature, min; t3 - the time required to cool down the can, min; T - the sterilization temperature to be reached, °C.

1. Normal pressure sterilization method

The normal pressure sterilization method refers to the method of sterilizing in a medium with normal pressure of 100°C or below. Sterilization in a medium with normal pressure below 100°C is also called pasteurization. Atmospheric pressure sterilization can be carried out in a vertical sterilizer or a rectangular water tank. After the water is boiled, it is immediately put into an iron cage or basket filled with cans. However, it should be noted that the temperature difference when the glass bottle enters the water should not exceed 60°C, otherwise the glass bottle will rupture. During sterilization, the cans should be kept 10~15cm below the water surface, the sterilization temperature should remain unchanged, and after the specified time, they should be taken out and cooled.

Pressure sterilization refers to a method of sterilizing in a heating medium above 100°C. The heating medium is steam or water. No matter which medium is used, high pressure is a necessary condition to obtain high temperature, so it is also called high pressure sterilization. Pressure sterilization has two forms: high-pressure steam sterilization and pressurized water sterilization. Metal cans are generally sterilized by high-pressure steam, while glass cans are mostly sterilized by pressurized water.

The high-pressure steam sterilization method is to put the cans into a sealed sterilizer, pass in steam at a certain pressure, remove the air and condensed water in the sterilizer, raise the temperature in the sterilizer to a predetermined heating temperature, and maintain it for a certain period of time to achieve sterilization. the goal of. The sterilization temperature is reflected by the pressure in the sterilization pot. Therefore, when the exhaust heats up, the air must be completely eliminated to make the pressure and temperature consistent.

The pressurized water sterilization method is to place cans in water for pressure sterilization. The boiling point of water under normal pressure is 100°C, and the boiling point of water after pressurization can reach more than 100°C. Therefore, according to the requirements of can sterilization, the water temperature can be reached to the required temperature by increasing the pressure of the sterilizer.

The specific operation method is: place the can in the sterilizer and seal it, open the water inlet valve, so that the water surface is about 15cm higher than the top layer, and there should be 40cm of space between the liquid surface and the top of the sterilizer to accommodate the compressed air. After water inflow is completed, close all exhaust valves and overflow valves. After checking the air pressure regulator and other instruments, send air to increase the pressure in the sterilizer until it is 54~82kPa higher than the saturated water vapor pressure corresponding to the sterilization temperature. , then put in steam to quickly increase the water temperature until the sterilization temperature, and start calculating the sterilization time.

In order to ensure uniform temperature during the sterilization process, an equal amount of steam-air mixture should be introduced from the bottom of the pot and released from the top of the pot every 15 to 20 minutes. The exhaust at the top of the pot must be kept unobstructed, so that air can be continuously introduced and exhausted. Air, stir continuously to keep the temperature in the sterilizer uniform.

When soft-packaged pet cans are heated and sterilized above 100°C, huge pressure is generated in the packaging bag due to the expansion of residual air, water vapor and food in the bag. When the pressure difference between the inside and outside of the bag reaches 98kPa, the flexible packaging will rupture.

In order to prevent the film from rupturing, the residual gas in the bag should be reduced as much as possible during sealing. Air must also be pressurized during the sterilization and cooling process. Pressurization generally starts when the temperature rises to 70~95°C. The amount of pressurization depends on the food temperature, heat, and The size of the flexible packaging, the amount of residual air, etc. vary.

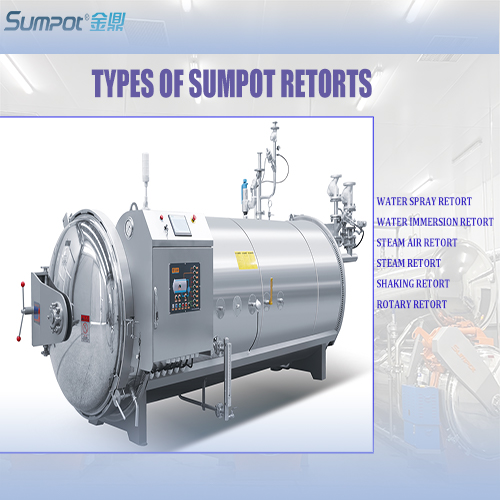

sumpot retort company can offer a wide range of pet food sterilization equipment such as spray sterilization retort autoclave, hot water immersion autoclave retorts, steam type autoclave retorts, steam air mixed autoclave retorts, we have rich experience for pet food retort machines over past 28 years history,if you are looking for retort autoclaves for pet food industry, please fill out our inquiry form, our sales expert will contact you very soon.

SUMPOT Advanced Water Spray Retorts

SUMPOT Advanced Water Spray Retorts

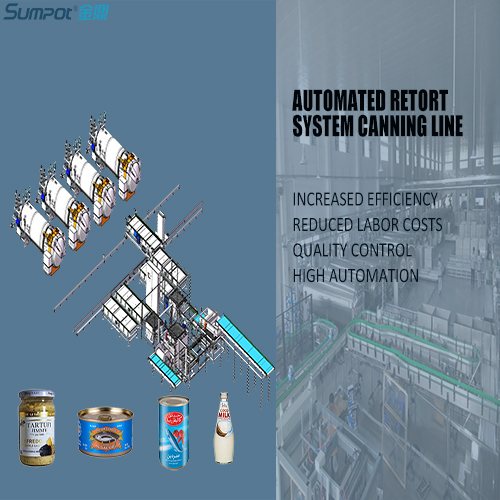

Automated Retort System Canning Line

Automated Retort System Canning Line

Types of Sterilization Retorts by SUMPOT

Types of Sterilization Retorts by SUMPOT