Food sterilization is to target food raw materials and processed products by sterilizing and removing microorganisms, the main factors that cause food deterioration, to stabilize food quality, effectively extend the shelf life of food, and thereby reduce harmful bacteria in food. In viable quantities, avoid ingestion of live bacteria causing human (usually intestinal) infection or bacterial toxins pre-produced in food causing human poisoning.

Ultra-high temperature short-term sterilization is to achieve sterilization by heating food to high temperatures (above 130 degrees Celsius) in an instant. It can be divided into two methods: direct heating and indirect heating. The direct heating method uses high-pressure steam to spray directly into the food to heat the food as quickly as possible, reaching 140 degrees Celsius ~ 160 degrees Celsius in a few seconds, maintaining it for a few seconds, then removing the moisture in the vacuum chamber, and then using a sterile cooler to cool it to room temperature. The indirect heating method uses plate heat exchangers and tube heat exchangers based on the viscosity and particle size of the food. Plate heat exchangers are suitable for liquid foods with pulp content not exceeding 1% to 3%.

The tubular heat exchanger has a wide range of product adaptability and can process liquid foods such as concentrated fruit and vegetable juices with high pulp content. Tubular heat exchangers can be used for products that would cause coking or clogging when using plate heat exchangers, and whose viscosity is not sufficient to use scraper heat exchangers. The effect of ultra-high temperature instant sterilization is very good. It can almost meet or approach the requirements of complete sterilization. Moreover, the sterilization time is short, the nutrients in the materials are destroyed less, the food quality is almost unchanged, and the nutritional component preservation rate reaches more than 92%. The production It is very efficient and more effective than the other two thermal sterilization methods.

The ultra-high temperature sterilization device combined with food aseptic packaging technology has developed rapidly at home and abroad, and has now developed into a high-tech food sterilization technology. At present, this sterilization technology has been widely used to sterilize products such as milk, soy milk, wine, juice, and various beverages. Food can also be bagged and immersed in hot water at this temperature for sterilization.

In the food sterilization industry, food thermal sterilization is currently the more mainstream form of sterilization. The sterilizing pot (sterilizing retort) plays a decisive role.

Fully automatic water spray sterilization retorts

High temperature short-term sterilization. A small amount of process water circulates quickly to quickly reach the predetermined sterilization temperature. There is no need to exhaust before heating up, saving 30% energy than traditional steam sterilization retorts; sterilization temperature and pressure are independently controlled. It can meet the sterilization requirements of various packaging forms (such as iron cans, glass cans, flexible packaging, PP bottles, etc.), which not only improves the utilization rate of the equipment, but also saves unnecessary repeated investment;

.Indirect micro-cooling, cooling water and process water are not in contact, avoiding secondary contamination of food, and there is no need to treat the cooling water;

The sterilizing retort is equipped with four movable temperature sensing tandem heads, which can monitor the F value in the center of the food and the heat distribution in the retort at any time, and understand the heat penetration (the time it takes for the temperature to reach the geometric center of the food from the surface of the food) at any time.

.The entire sterilization process is fully automatically controlled by PLC, and the heat distribution temperature in the retort is controlled within ±0.5°C. It can be heated in multiple stages to save energy; it is equipped with an F value measurement function; it can store 100 sterilization formulas;

The process water preheating system ensures that hot-filled products receive a continuous heating process;

Steam sterilization kinetic energy is optional; automatic upper and side door openings are optional;

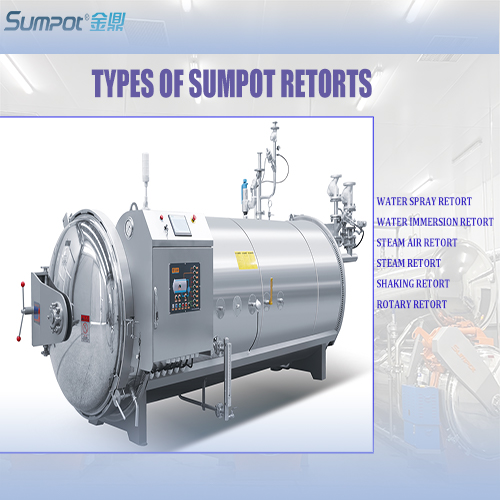

sumpot retort autoclave company has a 28 years of manufacturing various types of food and beverage sterilization machinery, including water spray retorts, hot water immersion retorts, steam retorts, steam air retorts, if you need this type of machinery, just fill out our inquiry form, we will contact you very soon.

The entire sterilization process is automatically completed in strict accordance with the preset process formula. The formula is equipped with multi-level passwords to eliminate the possibility of misoperation;

After the device is restored after a power outage, the program can automatically restore to the state before the power outage;

The retort body is insulated with aluminum silicate wool and polyurethane foam, which reduces the heat loss of the kettle body, saves steam energy, and meets low carbon and low emission requirements;

The cauldron door is equipped with a triple safety interlocking device, which can effectively prevent workers from misoperation and avoid accidents;

It adopts dual safety valves and dual pressure sensing controls to eliminate potential safety hazards.

SUMPOT Advanced Water Spray Retorts

SUMPOT Advanced Water Spray Retorts

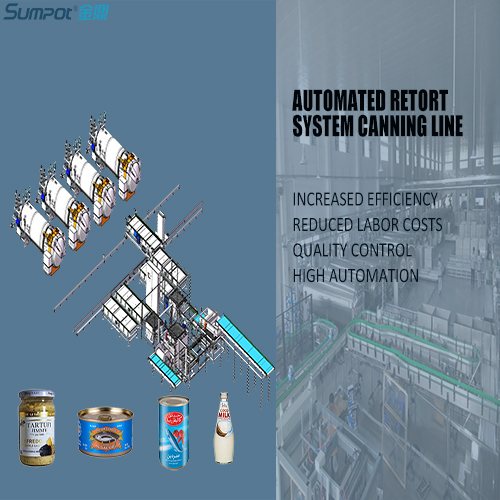

Automated Retort System Canning Line

Automated Retort System Canning Line

Types of Sterilization Retorts by SUMPOT

Types of Sterilization Retorts by SUMPOT