Pasteurization: Generally refers to the pasteurization method, also known as low-temperature sterilization. This method uses a relatively low temperature (generally 60-82°C) to heat the food within a specified time to achieve sterilization. Purpose, it is a method that can achieve the purpose of disinfection without damaging the quality of food. High-temperature sterilization: It is a traditional sterilization mode. It generally uses high-temperature and high-pressure sterilization methods. It requires packaging materials to have high isolation and certain cooking resistance.

The high-temperature sterilizing retort has the advantages of good energy saving effect, high productivity, automatic temperature display control, wide adjustment range, high control accuracy, corrosion resistance and noise reduction, and easy cleaning. It is widely used in food, juice, pharmaceutical, chemical, beverage and other industries. As a Necessary equipment for heating, cooling, heat preservation, sterilization, processing or storage of liquids.

The difference between pasteurization and high temperature retort sterilization

1. Different concepts (1) Pasteurization, also known as low-temperature disinfection and cold sterilization, is a disinfection method that uses lower temperatures to kill germs while keeping the flavor of the nutrients in the items unchanged. Specifically: Using a relatively low temperature (generally 60-82°C) to heat food within a specified period of time to achieve the purpose of sterilization is a method that can both

A method to achieve the purpose of disinfection without damaging the quality of food. (2) High-temperature sterilization, generally sterilizing at 135°C or above for several seconds, is a traditional sterilization mode. It uses high pressure and high temperature to sterilize. It requires packaging materials to have high isolation and a certain resistance to cooking. From the nutritional point of view, In terms of ingredients, high-temperature bacteria will destroy more nutrients than pasteurization due to the higher temperature. The main damage is trace nutrients such as vitamins, and there is not much difference in other proteins, fats, etc.

2. Storage conditions and shelf life are different.

Pasteurized milk can be stored at 2-8°C for 3-10 days; high-temperature sterilized milk can be stored at room temperature for 3-6 months, and bagged ultra-high temperature sterilized milk can also be stored for 1.5 months.

3. Disadvantages are different. Taking milk sterilization as an example, pasteurization does not heat the object to the boiling point, so some bacteria will remain, making the storage time short. After heating, it needs to be cooled quickly to about 4°C, so the cooling time is increased. Cost; High-temperature sterilization heats the object to the boiling point, which will volatilize some nutrients. The advantage is that it can be kept for a long time and will not deteriorate if left at room temperature for half a year. The cost is higher than that of Barba.

The sterilization method is low, suitable for things that need to be stored for a long time.

Generally speaking, pasteurization and high-temperature sterilization each have their own advantages and disadvantages. Different manufacturers and consumers can choose the sterilization method and milk type that suits them according to their own needs and preferences.

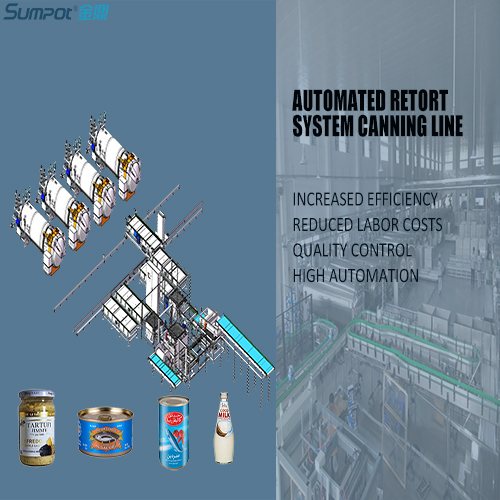

Automated Retort System Canning Line

Automated Retort System Canning Line

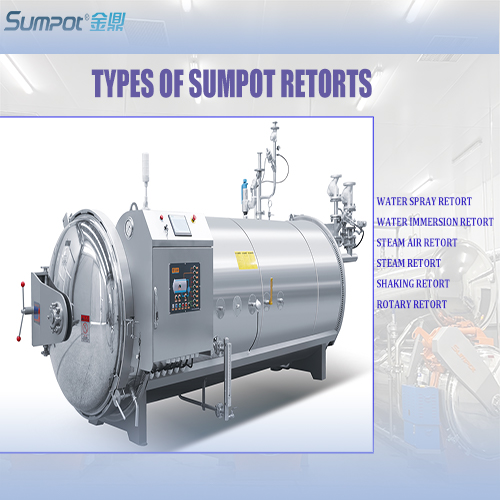

Types of Sterilization Retorts by SUMPOT

Types of Sterilization Retorts by SUMPOT

SUMPOT Water Immersion Retort Machine

SUMPOT Water Immersion Retort Machine