During the high-temperature sterilization of food, the main target of sterilization is Helicobacter botulinum. This bacterium can produce toxins that can cause fatal harm to the human body. It is a heat-resistant anaerobic bacterium. It takes about three minutes in an environment of 121°C. It will lose biological activity in about 6 hours at 100℃. Of course, the higher the temperature, the shorter the survival time of the pathogen. After scientific testing, sterilization is more suitable at 121°C. At this time, the packaging has good heat resistance and the food tastes better. When sterilized at 121°C, the F value in the center of the food reaches 4, and Helicobacter botulinum will not be detected in the food, meeting the requirements for commercial sterility. Therefore, when we sterilize meat products, the temperature is generally controlled at around 121°C. Too high a temperature will have a negative impact on the flavor of the food!

1. Hot water circulation sterilization: During sterilization, all the food in the pot is soaked in hot water. In this way, the heat distribution is relatively even.

2. Steam sterilization: After the food is put into the pot, water is not added first, but steam is directly added to heat it up. Since cold spots will appear in the air in the pot during the sterilization process, the heat distribution in this method is not the most uniform.

3. Water spray sterilization: This method uses nozzles or spray pipes to spray hot water onto the food. The sterilization process is through the nozzles installed on both sides or the top of the sterilization pot, spraying out mist-like waves. The hot water reaches the surface of the food, so it not only has a uniform temperature without dead spots, but also has rapid heating and cooling speeds. It can sterilize the products in the pot comprehensively, quickly and stably, and is especially suitable for the sterilization of soft-packaged foods.

4. Steam air mixed sterilization: This method of sterilization was introduced by France. It cleverly combines steam and water spray. A small amount of water is added into the pot to meet the cycle spray use. The steam directly enters the country, truly achieving short-term high efficiency. , energy saving, environmental protection and suitable for sterilization of special products.

High temperature sterilization is crucial for a food processing plant. It has the following two characteristics:

1. Disposable: The high-temperature sterilization work must be completed at one time from beginning to end without interruption, and food cannot be sterilized repeatedly.

2. The abstract nature of the sterilization effect: The effect of sterilized food cannot be detected with the naked eye, and the bacterial culture test also takes a week, so it is impossible to test the sterilization effect of each sterilized batch of food.

Based on the above characteristics, this requires manufacturers to:

1. First of all, the hygiene uniformity of the entire food processing chain must be ensured to ensure that the initial amount of bacteria in each bag of food is equal before bagging. This can ensure the effectiveness of the established sterilization formula.

2. The second requirement is to have sterilization equipment with stable performance and precise temperature control, which can execute the established sterilization formula without failure and with minimal error to ensure the standardization and uniformity of the sterilization effect.

SUMPOT Advanced Water Spray Retorts

SUMPOT Advanced Water Spray Retorts

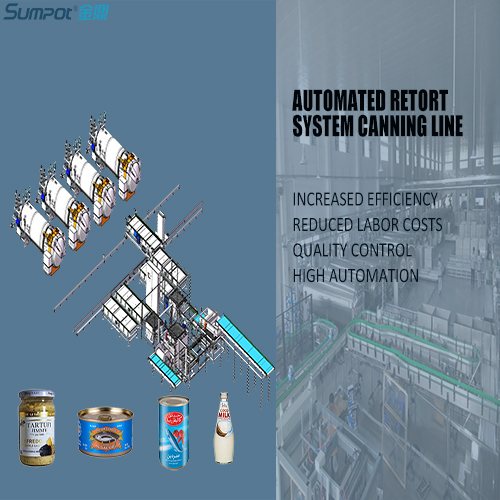

Automated Retort System Canning Line

Automated Retort System Canning Line

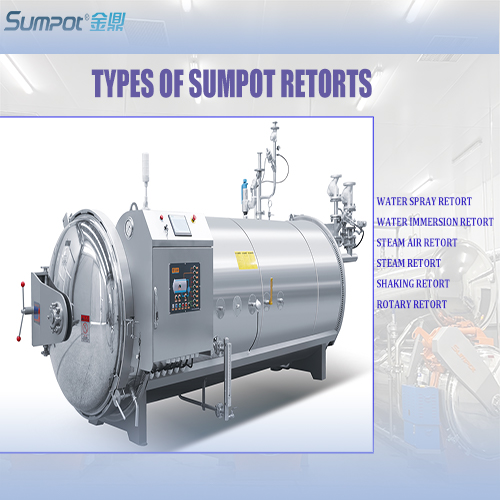

Types of Sterilization Retorts by SUMPOT

Types of Sterilization Retorts by SUMPOT